Topics

Thank you and report of "International Technical Exhibition on Image Technology and Equipment 2020"

Toshiba Teli Corporation participated in the International Technical Exhibition on Image Technology and Equipment (ITE) 2020 held at PACIFICO Yokohama from December 2 (Wed.) to December 4 (Fri.) to showcase high-pixel-count cameras with CoaXPress 2.0, Dual USB3, USB3, and other interfaces, various industrial cameras with different interfaces (CoaXPress, USB3, GigE, Camera Link cameras), and diverse inspection solutions.

As part of our efforts to prevent the spread of COVID-19, we also demonstrated the usefulness of our system to identify visitors who are not wearing a face mask and measure visitors’ body temperature at the entrance of our booth.

As an application example, we exhibited ViewLED from Toshiba Lighting & Technology Corporation, an LED light equipped with Teli’s camera.

We would like to express our sincere gratitude for all the people who visited our booth.

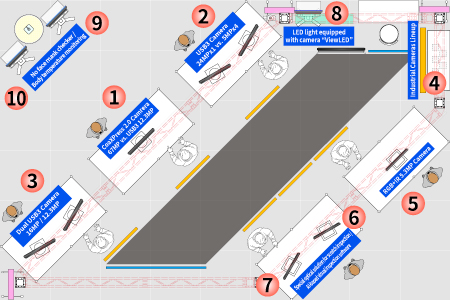

Descriptions of our booth

Click here for larger image

Our booth consisted of the following ten sections, each of which is described below;

- CoaXPress 2.0 camera: EX670AMG-X

- C-mount camera with Gen-4 24.5MP Pregius S; BU2409MCF

- Cameras with a Dual USB3 interface realizing 10Gbps transfer bandwidth; DDU1607MCF and DDU1207MCF

- Industrial cameras lineup

- RGB+NIR 5.3MP CMOS camera

- Special optical solution for scratch inspection

- Proposal for using artificial intelligence to save the labor required for visual inspection; PEKAT Vision

- LED light equipped with a camera; ViewLED

- System for identifying visitors who are not wearing a face mask

- Body temperature monitoring system

[ Please check out the Teli booth introduction video ! ]

Descriptions of each section 1 <High-definition camera area >

① CoaXPress 2.0 camera; EX670AMG-X (under development)

We showcased the EX670AMG-X 67-million-pixel (67MP) CMOS monochrome camera with four lanes of the latest CoaXPress V2.0 CXP-12 interface in comparison with the existing BU1207MG 12.28-million-pixel (12.3MP) CMOS monochrome camera with a USB 3.1 Gen 1 interface.

With the EX670AMG-X, we played a non-blurry high-definition video captured at a frame rate of 60 fps or more that simulates an inspection of printed circuit boards, showing square workpieces over a frame of 8,192-by-8,192 pixels. It was compared with an image captured by the 12.3MP camera to make the resolution of the EX670AMG-X stand out.

The latest TeliViewer viewer contained in TeliCamSDK, the latest software development kit, was used to import images. Whereas different viewers were previously necessary for each interface, TeliViewer provides connectivity, viewing, and control capabilities for USB3, GigE, and CoaXPress cameras, further increasing ease of use. In addition, TeliViewer provides enhanced image display processing, making it possible to obtain full high-speed performance from the camera.

[ Cameras and software used ]

- EX670AMG-X

https://www.toshiba-teli.co.jp/en/products/industrial-camera/coaxpress-camera-ex-ex670.htm - BU1207MG

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-bu1207m.htm - TeliViewer

[ Product leaflet ]

- EX670AMG-X

https://www.toshiba-teli.co.jp/pdf/catalog/fl_ex670amg_jp.pdf

* An English version will be published as soon as it becomes available.

[ Download a document containing exhibition panel image ]

- [ CoaXPress 2.0 Camera (in Japanese) ]

* An English version will be published as soon as it becomes available.

[ Introduction video ]

② C-mount camera with Gen-4 24.5MP Pregius S; BU2409MCF (new product)

We demonstrated the BU2409MCF color camera incorporating the Gen-4 24.47-million-pixel (24.5MP) Pregius backside-illuminated CMOS image sensor from Sony Corporation in comparison with four units of the BU505MCF 5.01-million-pixcel (5MP) color CMOS camera that together provide a pixel count equivalent to the BU2409MCF.

Despite a high pixel count of 24.5MP, the CMOS image sensor of the BU2409MCF fits in a 1.2-inch optical format, making it possible to realize the BU2409MCF as a C-mount camera. Therefore, the BU2409MCF serves as an easy replacement for conventional C-mount cameras when you need a higher resolution.

A single unit of the 24.5MP BU2409MCF suffices when you need a resolution achievable with four units of a 5MP camera.

[ Cameras and software used ]

- BU2409MCF

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-bu2409m.htm - BU505MCF

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-bu302m-bu505m.htm - TeliViewer

[ Download a document containing exhibition panel image ]

- [ C-mount camera with Gen-4 24.5MP Pregius S (in Japanese) ]

* An English version will be published as soon as it becomes available.

[ Introduction video ]

③ Cameras with a Dual USB3 interface realizing 10Gbps transfer bandwidth; DDU1607MCF (new product) and DDU1207MCF

We showcased a unique Dual USB3 camera with two channels of the USB 3.1 Gen 1 interface.

We demonstrated the new DDU1207MCF 12.28-million-pixel (12.3MP) CMOS color camera and the existing DDU1607MCF 16-million-pixel (16MP) CMOS color camera, showing non-blurry high-resolution images of a rotating object captured at high speed via an external trigger.

[ Cameras and software used ]

- DDU1607MCF

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-ddu1607m.htm - DDU1207MCF

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-ddu1207m.htm - TeliViewer

[ Download a document containing exhibition panel image ]

- [ Cameras with a Dual USB3 interface realizing 10Gbps transfer bandwidth (in Japanese) ]

* An English version will be published as soon as it becomes available.

[ Introduction video ]

Descriptions of each section 2 <Industrial camera lineup>

④ Industrial cameras lineup

We exhibited a panel showing the lineup of our major industrial cameras by interface and put them on display.

[ Camera series listings ]

- CoaXPress Camera

https://www.toshiba-teli.co.jp/en/products/industrial-camera/coaxpress-camera-ex-ex670.htm - Dual USB3 / USB3 Vision Camera

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-ddu1607m.htm

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-ddu1207m.htm - USB3 / USB3 Vision Camera DU Series

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-du1207m.htm - USB3 / USB3 Vision Camera BU Series

https://www.toshiba-teli.co.jp/en/products/industrial-camera/index.htm/#cat-usb-camera-bu - GigE / GigE Vision Camera BG Series

https://www.toshiba-teli.co.jp/en/products/industrial-camera/index.htm/#cat-gige-camera-bg - Camera Link Camera BC Series

https://www.toshiba-teli.co.jp/en/products/industrial-camera/index.htm#cat-cameralink-bc - Camera Link Camera CSC Series

https://www.toshiba-teli.co.jp/en/products/industrial-camera/index.htm#cat-cameralink-csc

[ Download a Lineup table ]

Descriptions of each section 3 <System solution area>

⑤ RGB+NIR 5.3MP CMOS camera (pre-launch exhibit)

We demonstrated an RGB+NIR camera with a 5.33-million-pixel (5.3MP) CMOS image sensor capable of capturing visible and near-infrared (NIR) light simultaneously. The demonstration was designed to inspect the printing conditions on the surface of packages via RGB images and internal foreign substances and dents via NIR images at the same time.

Since one of the pixels of the color filter of this camera is allocated to the NIR region, it is capable of simultaneous capture of RGB and NIR images, eliminating the need to build a large system composed of multiple monochrome, color, and other types of cameras and therefore making it possible to reduce system size.

[ Cameras and software used ]

- RGB+NIRcamera (pre-launch exhibit)

- Dedicated viewer software

[ Download a document containing exhibition panel image ]

- [ RGB+NIR camera (in Japanese) ]

* An English version will be published as soon as it becomes available.

[ Introduction video ]

⑥ Special optical solution for scratch inspection (pre-launch exhibit)

We showcased an optical solution capable of performing a scratch inspection with a single shot.A special optical system can display scratches on the surface of plastics in color without post-processing using a PC.

In a demonstration, its application software highlighted scratches in red and displayed the word “NG” when the red area exceeded a preset threshold.

This inspection system is an amalgamation of camera technologies of Toshiba Teli Corporation, special optical technologies of the Corporate Research & Development Center of Toshiba Corporation, and AI-based technologies of Toshiba Digital Solutions Corporation.

The special optical and AI-based technologies combine to colorize difficult-to-observe micron-scale superficial scratches and foreign substances as well as dents and uneven conditions on metal surfaces, allowing for easy identification.

Since this solution is capable of single-shot inspection, it can be incorporated into a continuously operating conveyor and simplifies post-processing, enabling high-speed automatic inspection and thus deriving the optimal performance from machine vision cameras.

[ Cameras and software used ]

- BU238MCF

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-bu238m.htm - TeliViewer

[ Download a document containing exhibition panel image ]

- [ Special optical solution for scratch inspection (in Japanese) ]

* An English version will be published as soon as it becomes available.

⑦ Proposal for using artificial intelligence to save the labor required for visual inspection; PEKAT Vision (pre-launch exhibit)

We demonstrated a scratch inspection for camera chassis, combining the PEKAT Vision deep-learning software from PEKAT s.r.o. in Czechoslovakia and Teli’s camera.

It required only two to three hours to teach the AI engine to recognize scratches and three to four hours for the learning, verification, and tuning of the AI engine. PEKAT Vision allowed us to create a highly accurate model in a relatively short time.

For the teaching work, we prepared only 30 sets of images of chassis with and without a scratch. You can provide a teaching set of images for PEKAT Vision simply by tracing scratches on the PEKAT Vision GUI just like on a graphics editor. Then, on a single click, PEKAT Vision does the rest of the work from learning to verification.

[ Cameras and software used ]

- BU238M

https://www.toshiba-teli.co.jp/en/products/industrial-camera/usb-camera-bu238m.htm - PEKAT Vision

[ Download a document containing exhibition panel image ]

- [ Proposal for using artificial intelligence to save the labor required for visual inspection (in Japanese) ]

* An English version will be published as soon as it becomes available.

Case study <Special corner>

⑧LED light equipped with a camera; ViewLED

As an application example, we exhibited ViewLED from Toshiba Lighting & Technology Corporation, an LED light equipped with Teli’s camera.

ViewLED is pre-equipped with a security camera, eliminating the need for electrical work to install a camera. In other words, electrical work for the installation of an LED light suffices. ViewLED allows security monitoring via Wi-Fi. (A wired connection was used for the exhibit.) Since nothing is generally placed under a ceiling light, ViewLED provides wide coverage and clear images.

The following are the major specifications of the pre-equipped camera;

- Sensor: 1/2.8-inch CMOS image sensor

- Resolution: 8MP

- Compression: H.264

- Output signal: Ethernet (wired LAN: 100BASE-TX, wireless LAN: IEEE 802.11b/g/n, 2.4 GHz)

[ Product used ]

- LED light equipped with a camera ViewLED

[ Download a document containing exhibition panel image ]

COVID-19 Infection spread prevention system <Booth entrance>

⑨ System for identifying visitors who are not wearing a face mask

At the entrance of our booth, we demonstrated a system for identifying visitors without a face mask and raising an alert.

A monitoring camera was set up at the back of the booth to capture the entrance area. When this system finds visitors without a face mask, it displays the alert “NO MASK” and tracks their faces.

In addition, the face attribute recognition function shows the estimated age and gender simultaneously.

[ Cameras and software used ]

- CI8001-D

- Milestone Smart Client / Intelligent viewer plugin

⑩ Body temperature monitoring system

In addition to the face mask recognition system, we demonstrated a thermographic camera to monitor visitors’ body temperature at the entrance of our booth.

Its monitoring/viewer software has been developed by Teli.

This system measures and displays the face temperature of the person standing right across the camera.

Digital signage at the venue

We showed our latest cameras on the digital signage at the back of the venue.

[ Video for the digital signage ]

International Imaging Seminar 2020

At the International Imaging Seminar held simultaneously with the ITE, Teli’s engineer presented a seminar entitled “Proposal of high-resolution, high-speed interface camera with the latest technology”.

【Click here for lecture video】

[ Seminar lecture video ]

- * Japanese lecture only

- * Provided by: Advanced Communication Media Co.,Ltd.

[ Seminar material ]

- Click here to download the seminar material (in Japanese).

* An English version will be published as soon as it becomes available.

Thank you for taking time in your busy schedule to attend the seminar.

* Pregius, Pregius logo, Pregius S and Pregius S logo are trademarks of Sony Corporation.

* Company name, logo or other names are trademark or registered trademark of related companies in some cases

Information including specifications, content of services and contact information, is current on the date of the press announcement, but is subject to change without prior notice.